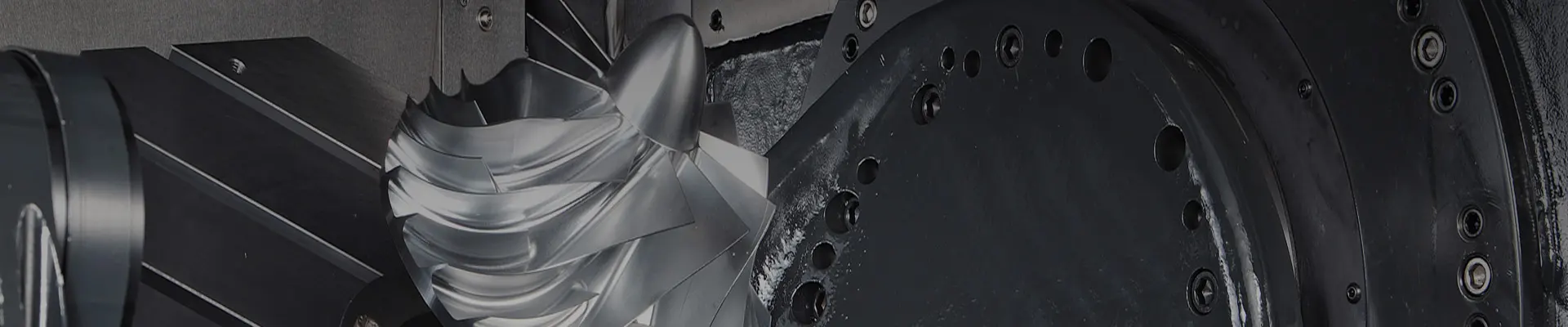

CNC Precision Turning Parts

As the professional manufacturer, we would like to provide you Dyfab CNC Precision Turning Parts. Precision CNC turning is an engineering process that utilizes a lathe to produce intricate, custom-designed parts. During this procedure, a single-point cutting tool is positioned parallel to the workpiece. As the material rotates at different speeds, the cutting tool moves across it, creating highly accurate circular cuts.

Send Inquiry

Ningbo Dyfab Industry Co.,Ltd is a specialized industrial manufacturer in China, that supplies a wide range of custom parts and products. We mainly produce precision CNC turning parts. There are more than 50 CNC machines in our facility, and more than 5 QC technicians. We are IATF 16949:2016; ISO 45001:2018; ISO 14001:2015; ISO 9001:2015 certified. If you need custom-made turning parts, please contact Dyfab, we can provide excellent quality and competitive price.

CNC precision turning parts are components manufactured using a CNC (Computer Numerical Control) lathe, a highly automated and precise machine tool. Here are key aspects and advantages of CNC precision turning parts:

Key Aspects of the CNC Precision Turning Parts

High Precision: CNC lathes are capable of producing parts with extremely tight tolerances, ensuring high accuracy and consistency.

Complex Geometries: These machines can create intricate and complex shapes that are difficult or impossible to achieve with manual turning.

Material Versatility: CNC lathes can handle a wide range of materials, including metals (such as aluminum, steel, brass, and titanium), plastics, and composites.

Efficiency: CNC turning is highly efficient, capable of producing large quantities of parts with minimal manual intervention.

Customization: CNC turning allows for easy customization and adjustments to the design specifications, accommodating specific requirements for each part.

Advantages of the CNC Precision Turning Parts

Consistency and Repeatability: Every part produced is identical, which is crucial for applications requiring uniformity.

Speed: The automated nature of CNC turning enables rapid production, reducing lead times.

Reduced Waste: Precision machining minimizes material waste, making the process more cost-effective and environmentally friendly.

Flexibility: CNC programs can be quickly changed or updated, allowing for easy switching between different parts or designs.

Quality Control: Advanced CNC machines often come with in-built quality control features, ensuring each part meets the desired specifications.

Applications of the CNC Precision Turning Parts

Automotive Industry: Manufacturing of engine components, shafts, and other precision parts.

Aerospace Industry: Production of high-precision parts for aircraft engines, landing gear, and other critical systems.

Medical Devices: Creation of surgical instruments, implants, and other medical components requiring high precision and biocompatibility.

Electronics: Fabrication of components for electronic devices, such as connectors and housings.

Industrial Machinery: Production of parts for various machinery and equipment used in manufacturing and production processes.